Needlepunch

Needlepunch is ideal for creating a flat, uniform fabric-like batt from natural, synthetic or blended fibers. WIN’s state of the art manufacturing allows weights as light as 2 ounces per square yard up to 30 ounces per square yard. Widths range from 124″ to 2″. The finished material can be tightly needled for a dense pad or soft and lofty for cushion wrap and everything in between.

Sonic Weld Process

Think of WIN’s sonic welding process as thread-free quilting capable of bonding multiple layers of material together without penetrating the materials. Weld fabrics, film and batting together quickly for a ready to finish multi-layer material. Perfect for custom insulation, apparel and top of the bed products. Choose from several attractive patterns. Available up to 60″ wide.

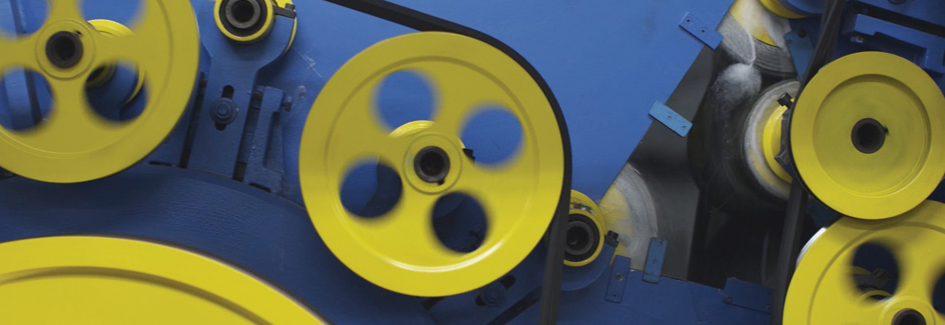

Thermal Bonding Process

WIN offers two types of thermal bonding. Calendaring and Through Air thermal bonding offer very different results. Calendaring is used for thin nonwovens and through air thermal bonding is used for high loft and densified fiber pads. Both methods produce consistent, uniform stable nonwovens in widths up to 120”. Inline slitting capabilities cost effectively completes the process.

Heat Activated Pressure Sensitive Adhesives

One of a kind permanent, heat activated adhesive web is printed on release paper with a tacky pressure sensitive adhesive giving it a repositionable value like no other! When fused between two fabrics a permanent is created. Often used by laser die cut manufacturers, label and patch manufacturers and for manufacturing fusible trim and ribbons.